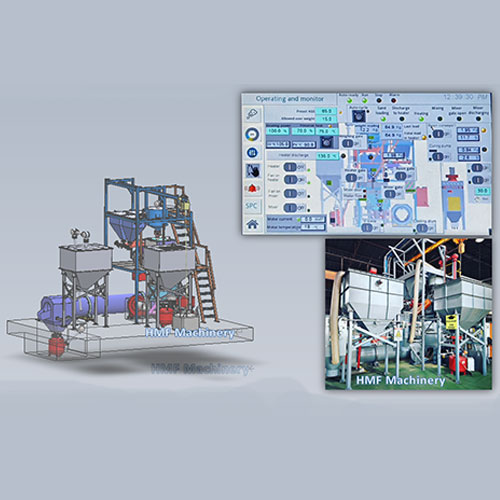

Resin coating sand plant, output can be 1.5ton-3ton/hour

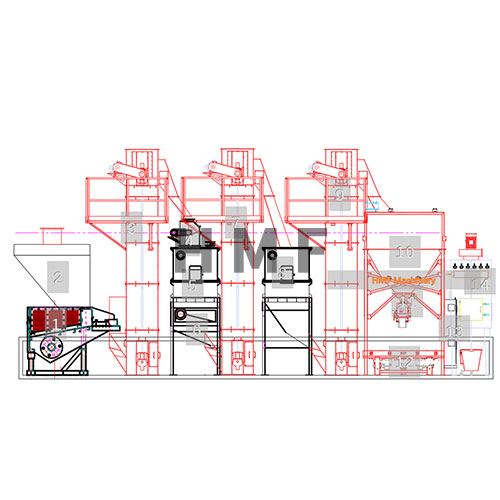

Machine line description

1.

Fresh sand storage hopper:

Sand loading volume=2.1CQM

One low level probe is installed, when sand inside the hopper is close to empty, will give signal to PLC. When the probe detects no sand, the red lamp on it will turn on.

2.

Fresh sand pneumatic transportation vessel.

Valid volume=100L·

One high level probe is installed. When the probe detects no sand, the red lamp on it will turn on.

The amount of sand feeding into vessel is decided by this sand level probe or by the timer of sand feeding , which will be set on HMI.

3.

Fresh sand weighing bucket

Valid volume=100L.

Fresh sand will be transported by pneumatic vessel to this hopper.

Include 3 loading cell, give signal to instrument to show loaded sand weight in the hopper.

Include 1 dust exhaust pipe, material PU , diameter=160mm, to led the dust to the filter device

4.

Dust filter device

Remove dust for fresh sand weighing bucket

Filter square=10SQM.

When dust air exhaust to this device, dust filtered on the cartridge, clean air will be exhausted to the outlet. For long time using, dust be filtered on the cartridge and covered on it will cause pressure to exhaust the clean air, when the pressure rise to 100/500pa (adjustable), the controller will start automatically to the blow out the dust covered on the cartridge filter.

5.

Electricity heater

Heating power: 80KW

Inside layer made by stainless SS304. Thickness=8mm.

Consistent by 36pcs of heating elements, 2.5kw of each, supply voltage=220V.

Heater cooling fan:2.2KW, Designed with hot air circling duct, there is no hot air will be discharge into the workshop, for energy saving and environment protection.

6.

3sets of additions storage hopper and conveyors.

One low level probe is installed on each storage hopper.

Each screw conveyor fitted with motor reducer, motor power=0.55KW, reducer ratio=40:1

7.

Additions weight bucket

the 3 type additions will be conveyed to this bucket to measure the weight before feed into mixer.

8.

Curing container with low lever sensor and magnetic pump.

9.

Sand mixer

Mixing motor power=21KW, cooling fan=3KW

Fitted with stainless liner and cooling layer around the mixing drum.

Mixing current measuring instrument connect to PLC, monitor mixing result and motor running status. Over load current data can be set on HMI.

10.

Vibrating sieve

Vibrating motor=0.55KW

Fitted with stainless wire mesh

11.

Cooling drum

Rotation driving motor reducer: 2.2KW

With circling water interlayer for cooling production sand quickly.

12.

Production sand transportation vessel.

Valid volume=100L·

One high level probe is installed. When the probe detects no sand, the red lamp on it will turn on. So when the probe lamp switches on, means sand is full filled in the vessel. It starts to transport sand to the production hopper automatically. Every time the cooling drum stop, no maters sand in this vessel is full or not, it will start to transport automatically to empty sand inside it.

13.

Product sand storage hopper

Volume = 2.2CBM

Fitted with sand probe on the high level, when sand in this hopper is full, signal will be sent to PLC.

14.

Dust filter device

Remove dust for production sand storage hopper.

Filter square=10SQM, fitted with function of filter automatic cleaning controller.

15.

Electrical control panel

Omron PLC system and size 10 inch HMI

Heating control in the heating chamber by SCR.

Heating power rate can be set on HMI.

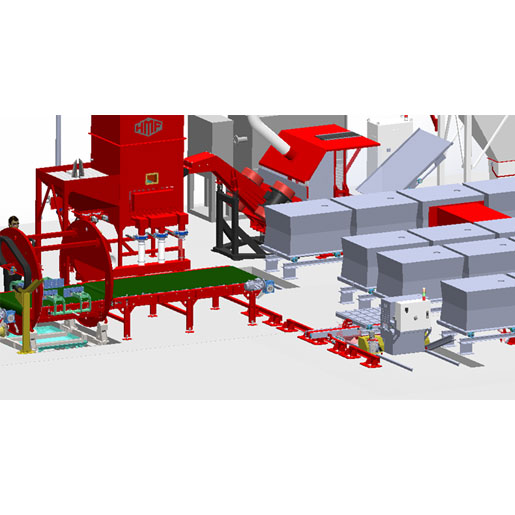

Description of LFC sand plant equipment

Description of LFC sand plant equipment Resin sand mixer OMEGA3 series

Resin sand mixer OMEGA3 series Resin sand mixer OMEGA4 series

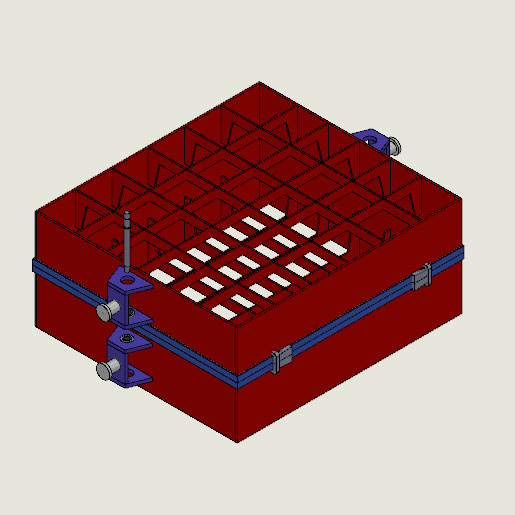

Resin sand mixer OMEGA4 series Shot-blasting turbine spare parts

Shot-blasting turbine spare parts Hooks hanger shotblasting plant type

Hooks hanger shotblasting plant type Q325 Shot blasting machine

Q325 Shot blasting machine

HOCHTECH MACHINERY

HOCHTECH MACHINERY