-

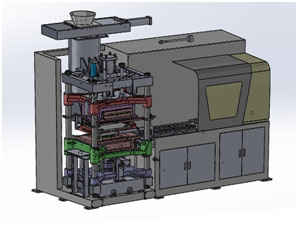

No bake sand plant & molding

-

Description of LFC sand plant equipment

Description of LFC sand plant equipment

Description of LFC sand plant equipmentDescription of LFC sand plant equipment

More -

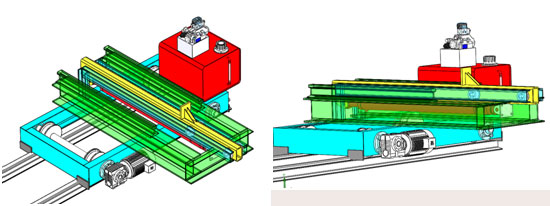

Resin sand mixer OMEGA3 series

Resin sand mixer OMEGA3 series

Resin sand mixer OMEGA3 seriesResin sand mixer OMEGA3 series Mixing output from 10-25TPH FIRST STAGE ARM ROTATION DRIVEN BY GEAR R...

More -

Resin sand mixer OMEGA4 series

Resin sand mixer OMEGA4 series

Resin sand mixer OMEGA4 seriesRESIN SAND MIXER OMEGA4 SERIES MIXING OUTPUT FROM 10-30TPH 2 ARM DRIVEN BY GEAR REDUCER BELT CONVEYO...

More

-

Description of LFC sand plant equipment

- Green sand plant & molding

-

Shot blasting equipment solution

-

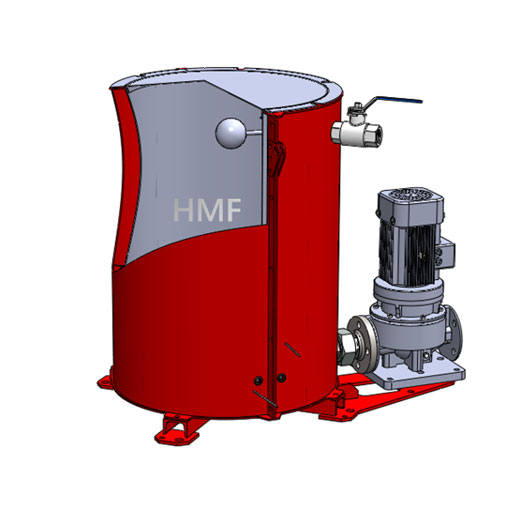

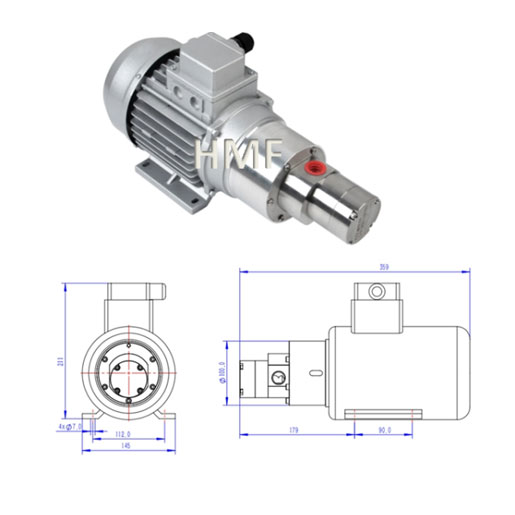

Shot-blasting turbine spare parts

Shot-blasting turbine spare parts

Shot-blasting turbine spare partsShot blastingQO34High alloy chrome castingsHMF Shot blasting turbineShot blasting liner

More -

Hooks hanger shotblasting plant type

Hooks hanger shotblasting plant type

Hooks hanger shotblasting plant typeTechnological equipment for foundry Hooks hanger shotblasting plant type VK including: - Shotblastin...

More -

Q325 Shot blasting machine

Q325 Shot blasting machine

Q325 Shot blasting machineSpecification: ITEM DESCRIPTION DATA 1 BLASTING WHEEL QUANTITY 1 SET 2 DRIVING TYPE DIRECT BY MOTOR ...

More

-

Shot-blasting turbine spare parts

- Dedust and environmental equipment

- Home

- About HMF

- All Products

- Blog

- Contact Us

HOCHTECH MACHINERY

HOCHTECH MACHINERY